The Grindersmen Process

Step One: Carbide Cleaning

We clean each and every piece of carbide that enters our facilities. We use an industrial ultrasonic cleaner, that neutralizes and removes any dirt, grime, or lubricants that would be on a blade.

Step Two: Five Step Precision Inspection

Carbide Inspection

Carbide is analyzed

and examined for quality

and correctness.

Concentricity

Within 0.002 inch.

Tooth Run-Out

Within 0.005 inch.

Tolerances of

Specific Saw

Configuration

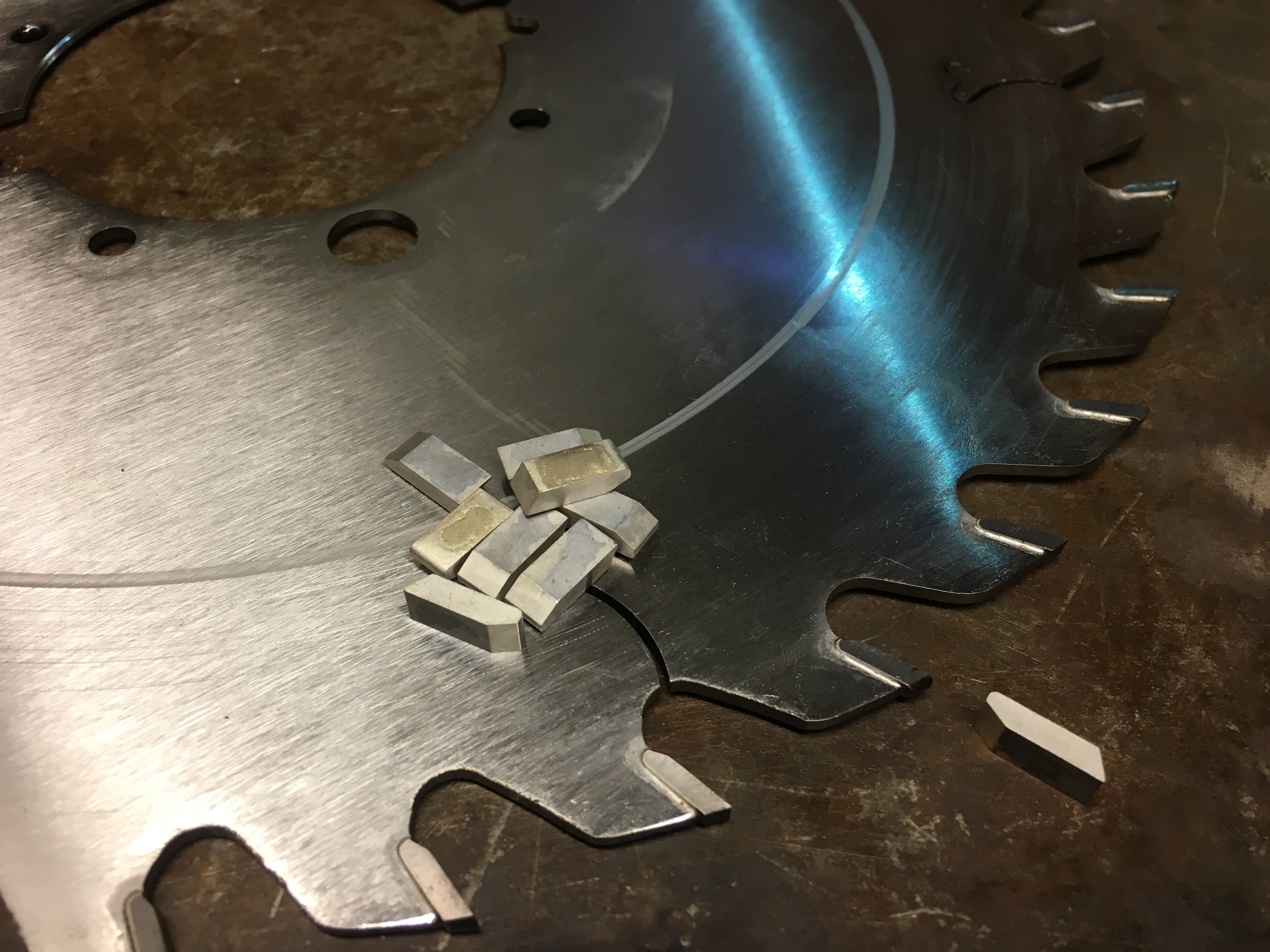

Step Three: Carbide Retipping

During the inspection process, we also look for any broken carbide teeth. If we find them, we replace them. Using Silver Solder and our advanced brazing technique, we put new teeth on and keep your blades cutting sharper and lasting longer.

Step Four: Grinding and Honing

We use the latest in CNC Sharpening and Manual Techniques to make sure our carbide circular blades and other carbide tooling is the sharpest possible. We make sure our blades are honed correctly, so they stand up to the test when our clients use them. If you are interested in more information about our grinding technique. Check out our video!

Step Five: Wax Protection

Our final step is to clean and wax the carbide we process. We apply the wax to edges we sharpen to maintain the edge we put on them. This allows our carbide to stay sharp until you are ready to use it.

;

Ready to Maintain that Hone on Your Carbide?

If you are ready to have carbide that is sharp, that stays sharp and handled professional, Contact Us. We are ready to make your carbide sharp and your work a little easier!